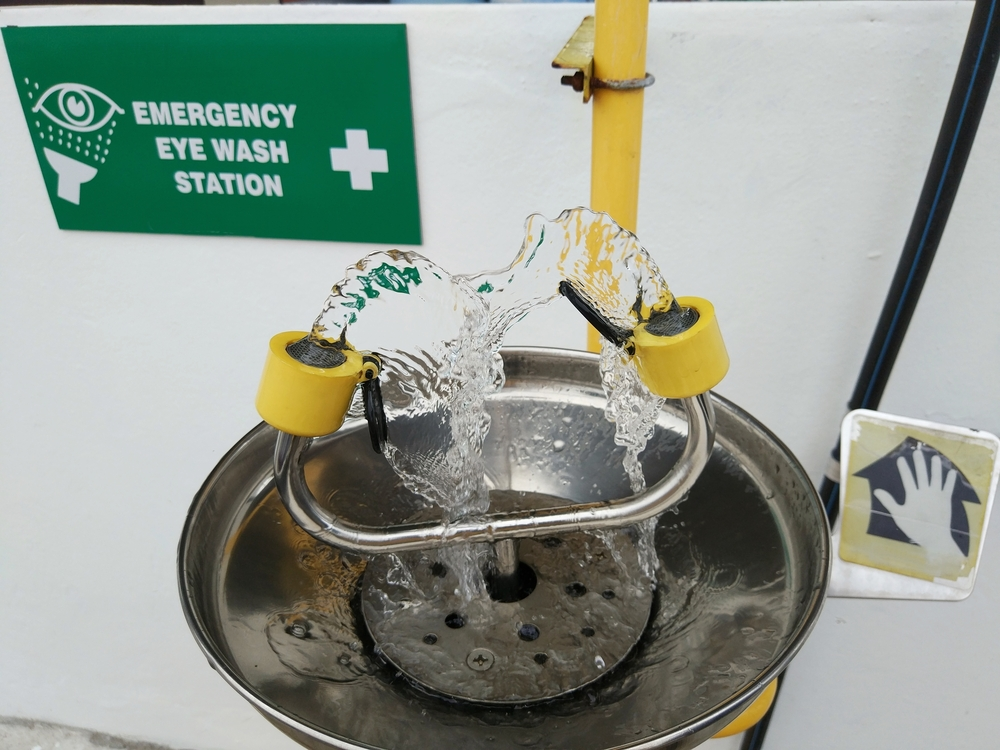

Where to Place Eye Wash Stations in Your Workplace: Best Practices for Safety

Ensuring workplace safety is essential, especially in environments where hazardous chemicals are present. An eye wash station is a critical piece of safety equipment that can prevent serious injuries. In this guide, we’ll cover best practices for placing eye wash stations and discuss other safety tools like waterproof work gloves, retro-reflective tape, and first aid signs to print.

Introduction

Eye wash stations are a must-have in workplaces where employees are at risk of eye injuries from chemicals or debris. Regulatory bodies like OSHA require these stations to be easily accessible in hazardous areas. Additionally, workplaces should be equipped with hand sanitizer equipment and waterproof work gloves to ensure full protection for employees.

Identifying Hazard Zones

Start by identifying high-risk zones where chemicals, debris, or irritants could pose a threat to employees' eyes. These areas could be chemical labs, manufacturing zones, or construction sites. Using retro-reflective tape in these zones can improve visibility, ensuring that employees can quickly find the eye wash station in an emergency.

Placement Guidelines

When positioning an eye wash station, it’s crucial to follow safety regulations and best practices:

Proximity to hazards: The station should be within 10 seconds (about 55 feet) of potential hazards.

Accessibility: Ensure clear, unobstructed pathways to the station. You might also use reflective tape pink to mark the path and make it highly visible in case of an emergency.

For businesses utilizing adjustable cable locks in their lockout/tagout procedures, it's essential to ensure that these devices don't obstruct access to safety equipment like eye wash stations.

Common Locations for Eye Wash Stations

Common places for eye wash stations include manufacturing areas, laboratories, warehouses, and construction sites. For outdoor locations or areas with exposure to chemicals, waterproof work gloves are a key part of employee safety equipment. Pairing stations with proper signage ensures compliance and safety.

Installation Tips

Install eye wash stations at an accessible height and ensure the water temperature is between 60-100°F. Proper signage is vital, and using a DuraLabel Toro Max printer can help you create clear, durable labels. To further improve safety, use retro-reflective tape around stations to make them more visible.

Maintenance & Testing

Ensure your eye wash station is ready for use by performing weekly checks and regular cleaning. Testing should confirm that the station can provide 15 minutes of continuous water flow. Lock the station securely when not in use with adjustable cable locks to prevent tampering.

Employee Training

Training employees on the proper use of eye wash stations is crucial. Regular safety drills should include instructions on how to use the station. Employees should also be trained in using hand sanitizer equipment and waterproof work gloves, as well as understanding safety signage like first aid signs.

Final consideration

Placing eye wash stations strategically in hazard zones ensures compliance and enhances workplace safety. Additional safety tools, like retro-reflective tape, waterproof work gloves, and first aid signs to print, can help protect employees. With the right placement, signage, and training, your workplace will be well-prepared for emergencies.

FAQs

- What is an eye wash station?

An eye wash station is a safety device used to flush the eyes in case of exposure to harmful chemicals or debris.

- Where should eye wash stations be placed?

Eye wash stations should be placed within 10 seconds (55 feet) of hazardous areas where chemicals or debris are present.

- How often should eye wash stations be checked?

They should be tested weekly to ensure they function properly and provide clean water for at least 15 minutes.

- What other safety equipment should be nearby?

In addition to an eye wash station, it’s important to have hand sanitizer equipment, waterproof work gloves, and clear first aid signs in the area.

- Why use retro-reflective tape near eye wash stations?

Retro-reflective tape improves visibility, especially in low-light conditions, helping employees quickly locate the station during an emergency.

- Can I print first-aid signs myself?

Yes, you can create and print first aid signs using a DuraLabel Toro Max printer for durable and clear safety labels.