DURALABEL PRINTER STARTER KITS

$6,228.00

$4,982.00

$10,531.00

$8,424.00

$13,101.00

$10,480.00

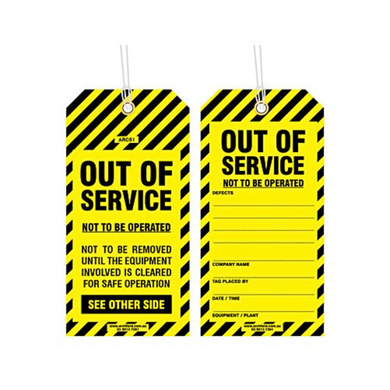

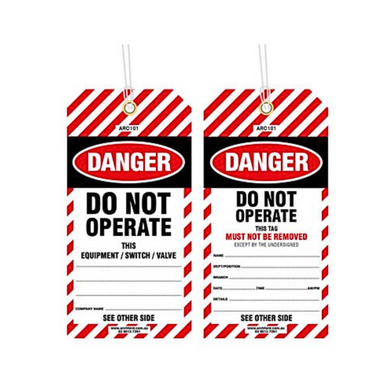

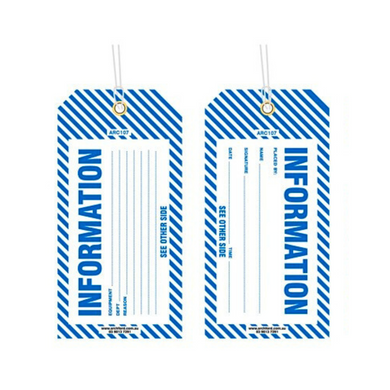

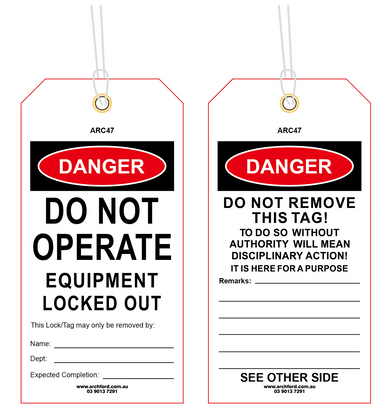

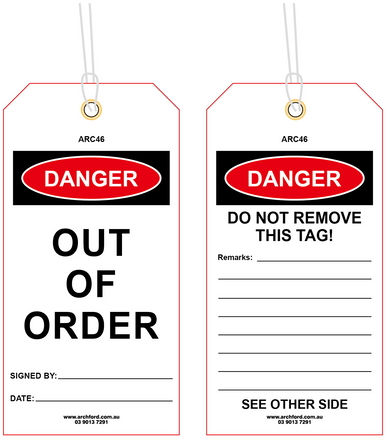

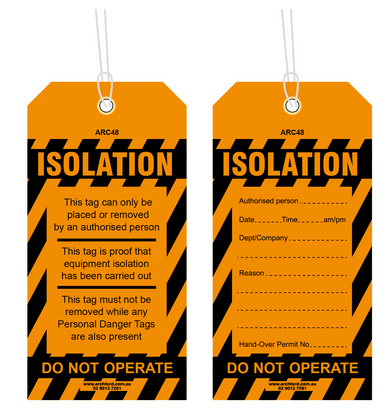

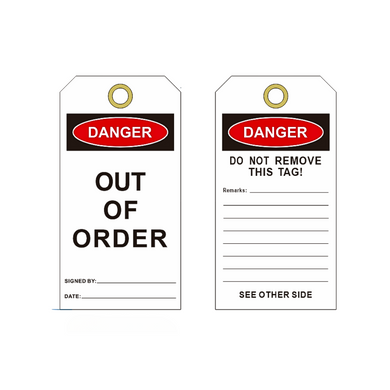

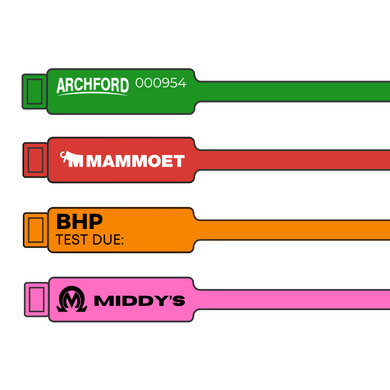

SAFETY TAGS

Same Day Shipping

Sold Out

$490.00

$35.00

$35.00

Sold Out

$17.00

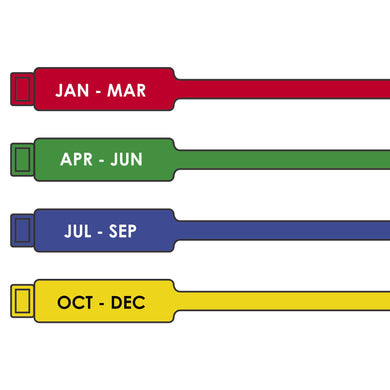

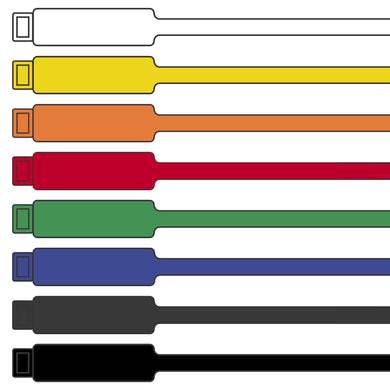

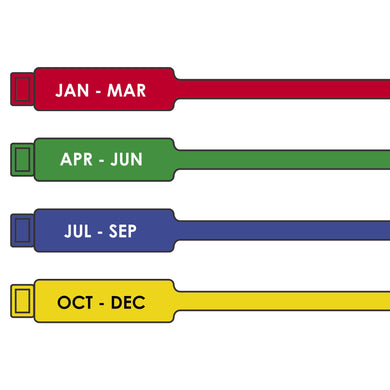

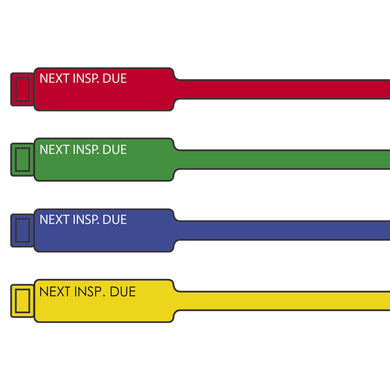

Inspection Tags

Same Day Shipping

PERSONAL LOCKOUT KITS

$385.00

Recommended By

Free AUS Shipping on Online Orders Over $199

14-days Easy Returns*

Secure Payment Checkout