How to Choose the Right Floor Tape for Your Warehouse Needs?

Table of content

- Introduction

- Understanding Distinctive Sorts of Floor Tape

- How to Select the Right Floor Tape for Your Warehouse?

- Application and Maintenance

- Complementary Security Tools

- Summarizing

Understanding Distinctive Sorts of Floor Tape

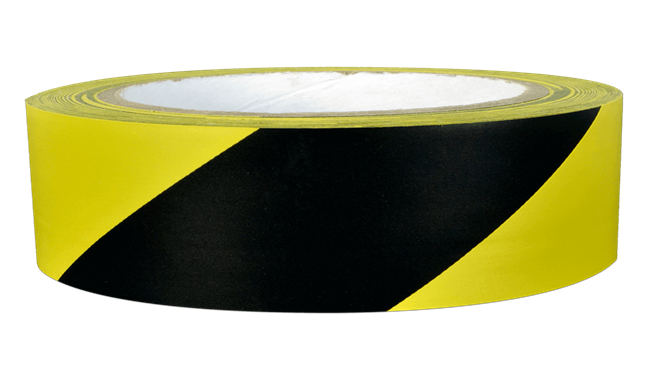

When selecting floor tape, it's important to understand the various types available and their specific applications:

- Fluorescent Tape: flourescent tape is known for its vibrant, high-visibility colors. This type of tape is ideal for marking critical areas such as walkways, risk zones, and safety perimeters. Its bright colors make it highly visible even in low-light conditions, pivotal in a warehouse environment where visibility can frequently be compromised.

- Reflective Tape: Reflective tape enhances visibility by reflecting light. This is particularly useful in poorly lit areas or where extra permeability is required. It can be combined with fluorescent tape for improved effectiveness.

- Anti-Slip Tape: For areas prone to spills or where safety is a major concern, anti-slip tape gives additional footing. This tape helps avoid slips and falls, decreasing the chance of mischances in high-traffic areas.

- Electrical Tape: Often used for temporary markings or insulation, electrical tape is less durable than other types but can be valuable for short-term needs or particular tasks.

How to Select the Right Floor Tape for Your Warehouse?

Selecting the appropriate floor tape for warehouse applications includes a few key considerations:

- Durability: The floor tape must be able to withstand the daily wear and tear of a warehouse environment. High-traffic regions and zones uncovered to apparatus or chemicals require solid tape.

- Adhesive Strength: A strong cement is significant to guarantee the tape remains intact. In a warehouse setting, where tape may be uncovered to moisture, chemicals, or heavy gear, the cement must be robust enough to resist peeling or lifting.

- Visibility: Enhancing visibility is an essential work of floor tape. Fluorescent tape is especially successful for checking critical ranges.

- Compliance with Floor Marking Standards: Adhering to floor marking standards is fundamental for maintaining safety and ensuring regulatory compliance. Measures set by organizations like OSHA indicate the colors and designs utilized for diverse sorts of floor markings.

Application and Maintenance

- Planning the Layout: Before applying the tape, plan the layout carefully. Identify key areas such as pathways, safety zones, and storage locations. Using an industrial label printer machine can help make custom labels for additional clarity and organization.

- Applying the Tape: Proper application is imperative for the tape's viability. Clean the surface thoroughly to expel dust and debris. Apply the tape firmly, utilizing a roller or squeegee to ensure great grip.

- Maintaining the Tape: Regular maintenance is necessary to keep the tape viable. Inspect the tape occasionally for signs of wear or damage and replace any sections that are peeling or worn. This ensures that the markings remain clear and functional, maintaining safety in the warehouse.

Complementary Security Tools

- LOTO Kit: A LOTO kit (Lockout/Tagout kit) is essential for managing lockout/tagout methods. This unit includes different devices and tags utilized to isolate machinery and equipment during maintenance.

- Lockout Station: A lockout station gives a centralized area for lockout devices and tags. It helps streamline the lockout/tagout process by keeping all vital equipment in one put, ensuring that safety strategies are taken after consistently.

- Labels: Labels are crucial for providing clear information about diverse zones and hazards. Custom labels made with a mechanical name printer machine can complement floor tape by offering extra details and information.

Summarizing

Choosing the right floor tape involves understanding the different sorts accessible and their particular applications. Fluorescent tape and reflective tape are fabulous choices for ensuring high visibility and safety. Compliance with floor marking guidelines is fundamental to meeting safety regulations and upgrading workplace safety.

Incorporating additional tools like a LOTO kit, lockout station, and labels further enhances your warehouse safety strategy. By carefully selecting and keeping up floor tape and utilizing complementary tools, you can make a safer, more organized warehouse environment that meets both operational needs and regulatory requirements.