Anti-Slip Industrial Tape Ideas for Workplace Safety

Why Anti-Slip Safety Measures Can’t Be Ignored

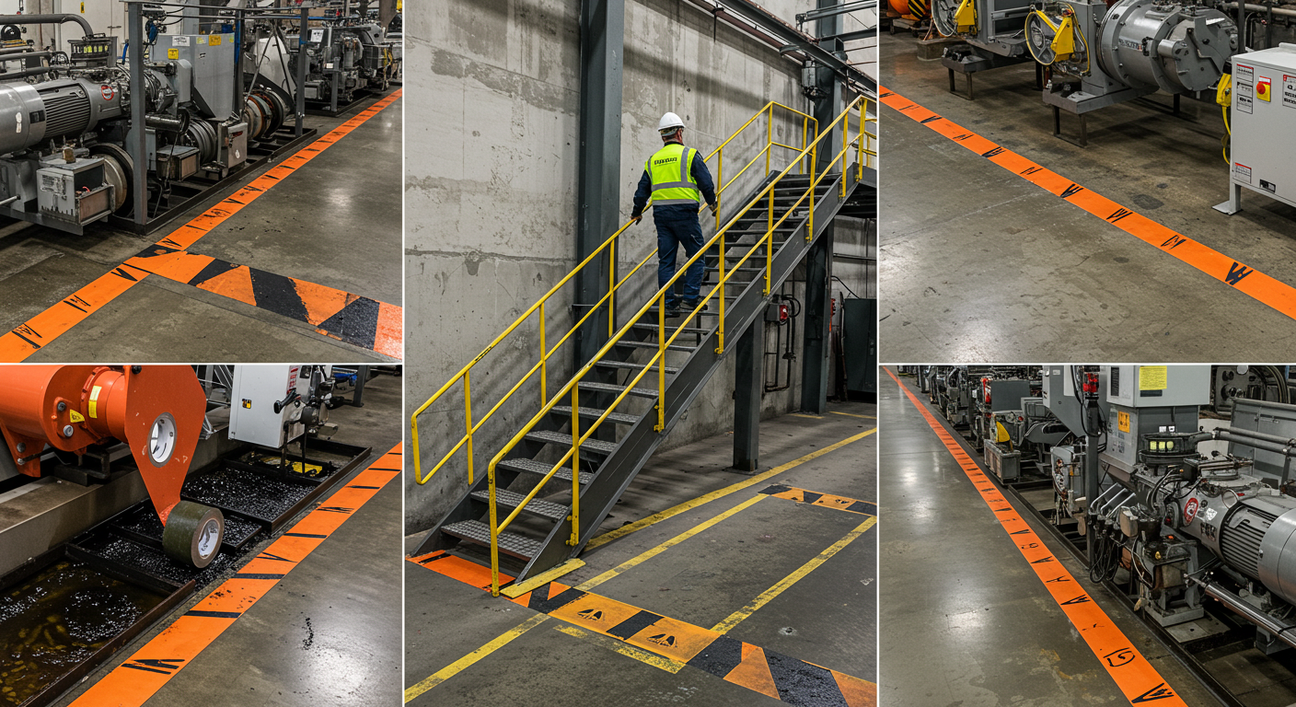

Falls remain one of the top causes of workplace injuries, many of which occur on stairs, ramps, and slick floor areas. In busy industrial environments, proper traction is more than a preference—it’s a necessity. That’s where anti-slip tape comes in. These simple yet powerful solutions create a friction-based layer on high-risk surfaces, dramatically reducing accidents.

What Is Anti-Slip Tape and How Does It Work?

Anti-slip tape—also known as non-slip tape or grip tape—is a specially engineered adhesive material layered with gritty or textured surfaces designed to enhance shoe traction. Available in various strengths and styles, it’s commonly used in warehouses, construction sites, and commercial buildings.

Whether you're outfitting stairways, walkways, or equipment zones, this cost-effective safety enhancement instantly upgrades hazard control.

Best Places to Use Anti-Slip Tape

Deploying traction tape correctly is key. Focus on:

-

Stairs: For maximum grip on each step edge

-

Ramps: Especially for anti-slip tape for ramps in loading docks or sloped corridors

-

Machine zones: Around wet machinery or wash bays

-

Entryways: Where weather increases slip risks

-

Ladders or platforms: Where vertical movement occurs

Use anti-slip industrial tape ideas for stairs and angled access points to reduce risk during movement in high-traffic areas.

Why Floor Safety Tape Works Well with Traction Tape

While anti-slip tape prevents falls, combining it with Floor Marking tapes adds clear visual direction. By partnering with Archford, you get industry-grade solutions tailored for both durability and compliance.

See Archford’s full line of safety floor tapes here—a key step in modern workplace hazard prevention.

How to Choose the Right Anti-Slip Tape for Your Environment

When selecting safety tape products, consider:

-

Surface Material – Smooth vs. textured floors

-

Traffic Volume – Light pedestrian or forklift-heavy?

-

Grip Grade – Standard, heavy-duty, or wet-area focused

-

Color Visibility – Use bold contrasts in dimly lit areas

-

Weather Resistance – For ramps or outdoor pathways

Tape width, adhesive strength, and UV resistance should also match your site’s specific needs.

Creative Ideas for Deploying Non-Slip Tape

Go beyond the basics with these implementation ideas:

-

Wrap stair nosings with yellow and black non-slip tape

-

Use glow-in-the-dark grip tape in emergency exits

-

Apply heavy-duty traction tape at entrances to break rooms or locker areas

-

Add custom warning messages on tape for special zones

-

Mix textured tape with signage to draw more attention

This adds both safety and operational clarity.

How to Install Anti-Slip Tape Correctly

Proper installation ensures durability and performance. Here’s how:

-

Clean thoroughly – Remove dirt, oil, or debris

-

Dry the area completely

-

Cut tape to fit using rounded corners

-

Apply pressure evenly

-

Allow 24–48 hours to cure

This minimizes edge lifting and maintains grip over time.

How Long Does Anti-Slip Tape Last?

You might wonder: How long does anti-slip tape last? In high-traffic indoor settings, it typically lasts 12–18 months. Outdoors, depending on UV exposure and surface wear, replacement may be needed closer to the 12-month mark.

Regular inspection and cleaning can help prolong usability.

Common Mistakes to Avoid with Anti-Slip Tape

Many facilities misuse their tapes or install them incorrectly. Here are key mistakes to steer clear of:

-

Using the wrong grit level for the space

-

Overlapping tapes—creates weak adhesion

-

Applying on wet or dirty floors

-

Ignoring edge sealing in wet zones

-

Choosing poor-quality adhesive

With Archford’s trusted lineup, you avoid quality shortfalls and ensure safety standards are met.

Budget-Friendly Tip: Tape vs. Flooring Overhaul

Instead of investing in costly floor upgrades, use anti-slip tape as a quick retrofit. When matched with Archford’s Floor Marking tapes, this gives you a versatile, visual, and frictional upgrade—without the expense or downtime of resurfacing.

Why Choose Archford for Anti-Slip and Floor Marking Solutions?

Archford stands out for its industrial-grade reliability and customer-focused service. From safety-enhancing Floor Marking tapes to grippy, weather-resistant options, Archford’s range is built for compliance and cost efficiency. Explore their floor marking solutions today and create a safer workspace from the ground up.

Essential Safety Solutions for Lockout, PPE, and Hazard Control

|

Tips / Guide Summary |

|

|

Select kits with multi-lock hasps, padlocks, and tags suitable for your industry. |

|

|

Use non-conductive or keyed-alike locks for easier and safer LOTO application. |

|

|

De-energize sources and use circuit breaker or plug lockout devices per procedure. |

|

|

Use proper devices for ball, gate, or butterfly valves; attach lock + tag always. |

|

|

Apply colored floor tape for equipment zones, hazard areas, and safe walking paths. |

|

|

Install on stairs, ladders, and wet areas to prevent slips, especially outdoors. |

|

|

Include hard hats, gloves, eye protection, respirators, and safety footwear in kits. |

|

|

Provide annual training and refreshers using real-world scenarios and documented tests. |

|

|

Include procedures, device inspections, employee responsibilities, and recordkeeping. |

|

|

Ideal for securing multiple valves or electrical panels with one locking point. |

Final Thoughts

Anti-slip protection shouldn’t be an afterthought—it’s a proactive safety strategy. Whether you’re securing stairways or highlighting sloped zones, grip tape and traction tape are your first line of defense. Pair these with Archford’s full suite of Floor Marking tapes, and your worksite will move closer to zero-hazard operations.

Small changes underfoot can have a big impact on workplace safety—and your team’s peace of mind.

FAQs

Q1: Can anti-slip tape be used outdoors?

Yes, but make sure it's rated for UV and weather resistance for outdoor longevity.

Q2: How do I maintain anti-slip tape?

Sweep regularly and use a mild cleaner. Avoid harsh solvents and pressure washers.

Q3: Where should grip tape be avoided?

Avoid unstable or rough surfaces like gravel or peeling paint areas.

Q4: How long does anti-slip tape last?

Typically 12–18 months, depending on foot traffic and exposure.

Q5: Is traction tape reusable?

No, it's designed for one-time adhesive use and should be replaced when worn.