Different Types of Industrial Tapes and How They’re Used

In industrial workplaces, warehouses, and factories, selecting the right tape is critical for efficiency, safety, and organization. Different types of industrial tapes and uses vary based on their strength, adhesion, and durability. Choosing the right tape ensures clear marking, hazard prevention, and smooth operations. Companies in Australia, like Archford, supply a wide range of industrial tapes, including vinyl tape, floor tape, safety tape, and specialty adhesive solutions to meet these needs.

Vinyl Tape: Versatile and Durable

Vinyl tape is one of the most commonly used industrial tapes due to its flexibility, durability, and resistance to moisture, chemicals, and temperature changes. It’s often used for:

Labeling and color-coding equipment, shelves, and inventory

Marking machinery for safety zones or operational instructions

Temporary or permanent repairs where strong adhesion is needed

Archford’s vinyl tape options come in multiple colors and widths, making it easy to identify hazards, organize storage, and maintain workplace efficiency. Its long-lasting nature makes it a reliable choice for indoor and outdoor applications.

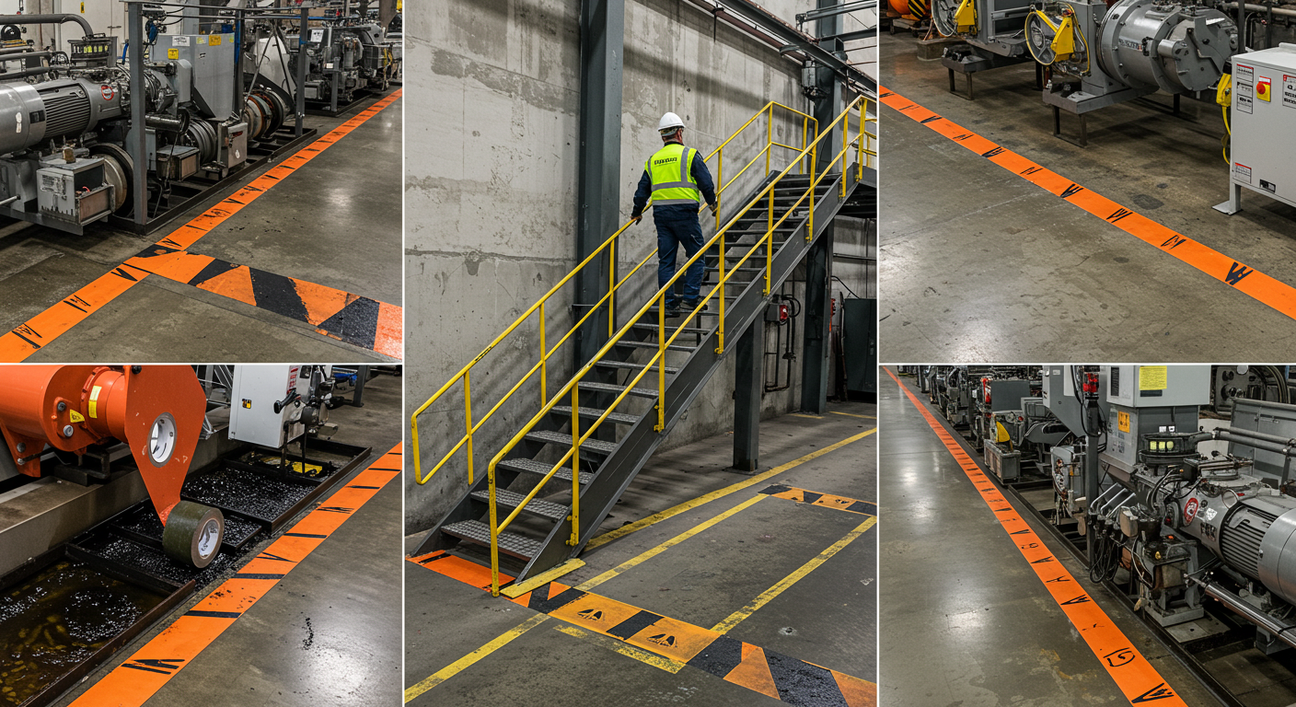

Floor Tape: Organizing Workspaces

Floor tape plays a key role in warehouses, factories, and large commercial areas by visually organizing spaces. It is primarily used for:

Marking pathways for employees and machinery to follow

Defining storage zones for pallets, tools, and raw materials

Highlighting hazardous areas to prevent accidents

Available in multiple colors and patterns, floor tape ensures that warehouse layouts are intuitive and safe. Archford’s floor tape is durable enough to withstand heavy foot traffic and machinery movement, providing a long-lasting solution for workplace organization.

Safety Tape: Ensuring Workplace Safety

Safety tape is designed for high visibility and often comes with reflective or fluorescent properties to make hazards obvious. Its main applications include:

Marking restricted areas or dangerous machinery

Highlighting emergency exits and evacuation routes

Indicating areas for personal protective equipment (PPE) compliance

By using safety tape, workplaces can reduce accidents, ensure compliance with safety regulations, and create a safer working environment. Archford’s safety tape is built to endure harsh industrial conditions, ensuring visibility even in low-light or high-traffic areas.

Industrial Adhesive Tapes: Strong Bonding Solutions

Industrial adhesive tapes are versatile and designed for tough applications where strong adhesion is critical. Common types include:

Duct tape for quick repairs and temporary fixes

Double-sided tape for mounting or securing materials

High-strength adhesive tape for heavy-duty equipment or machinery

These tapes are essential in construction, packaging, equipment maintenance, and manufacturing operations. Archford’s adhesive tape range is designed for industrial printer tips, manufacturing, and warehouse applications, offering reliable bonding on a variety of surfaces including metal, plastic, and wood.

Choosing the Right Tape for Your Needs: A Practical Tape Guide

When selecting the proper tape, consider these factors:

Surface type: Smooth surfaces need less aggressive adhesion; rough surfaces may need strong industrial adhesive tapes.

Indoor vs. outdoor use: Some tapes resist moisture and UV exposure for outdoor applications.

Durability: Choose tapes that can withstand foot traffic, machinery, or chemical exposure.

Following a tape guide approach ensures that every tape is used for its intended purpose, improving safety and efficiency. Archford provides clear labeling and guidance on matching tape types to specific applications.

Maintenance and Best Practices for Industrial Tapes

Proper handling and maintenance of industrial tapes ensure long-lasting performance:

Clean surfaces before applying tape for optimal adhesion

Avoid stretching or tearing the tape during application

Store tapes in a cool, dry place to maintain adhesive properties

Regularly inspect high-traffic areas to replace worn or damaged tape

These simple steps are part of label printer care and overall workspace management. Archford emphasizes these best practices to help businesses maintain a professional and safe environment.

Conclusion

Understanding the different types of industrial tapes and uses is key to creating safe, organized, and efficient workplaces. From vinyl tape for labeling to floor tape for organization, safety tape for hazard prevention, and industrial adhesive tapes for strong bonding, every type serves a specific purpose. By following proper application, storage, and maintenance practices, companies can maximize the benefits of industrial tapes.

For Australian businesses, Archford provides a wide selection of industrial tapes and accessories, ensuring reliability, safety, and durability in all industrial environments. For more information or guidance on selecting the right tape for your needs, contact Archford today .

FAQs

What is vinyl tape used for in warehouses?

Vinyl tape is mainly used for labeling, color-coding, and marking equipment or shelves.

How does floor tape improve warehouse safety?

Floor tape defines pathways, storage zones, and hazard areas to reduce accidents and improve organization.

Where should safety tape be applied?

Use safety tape to mark restricted areas, emergency exits, and zones requiring PPE.

What surfaces are industrial adhesive tapes suitable for?

They work on metal, plastic, wood, and other industrial surfaces requiring strong bonding.

How should I store industrial tapes to keep them effective?

Store tapes in a cool, dry place away from sunlight to maintain adhesive strength and longevity.