The Importance of Complying with Warehouse Floor Marking Standards Australia

In industrial and commercial settings, safety and efficiency are paramount. One often-overlooked aspect of maintaining a secure environment is adhering to warehouse floor marking standards in Australia. These standards help ensure that workspaces are organized and safe for workers, promoting smooth operations and reducing accidents. This article will guide you through the key aspects of complying with these standards, best practices, and the tools you need to implement them effectively.

Introduction

Warehouse floor marking warehouse floor marking standards Australia guarantees that workers and apparatus can explore spaces safely and efficiently, minimizing the risk of accidents and enhancing productivity.

What Are Warehouse Floor Marking Standards Australia?

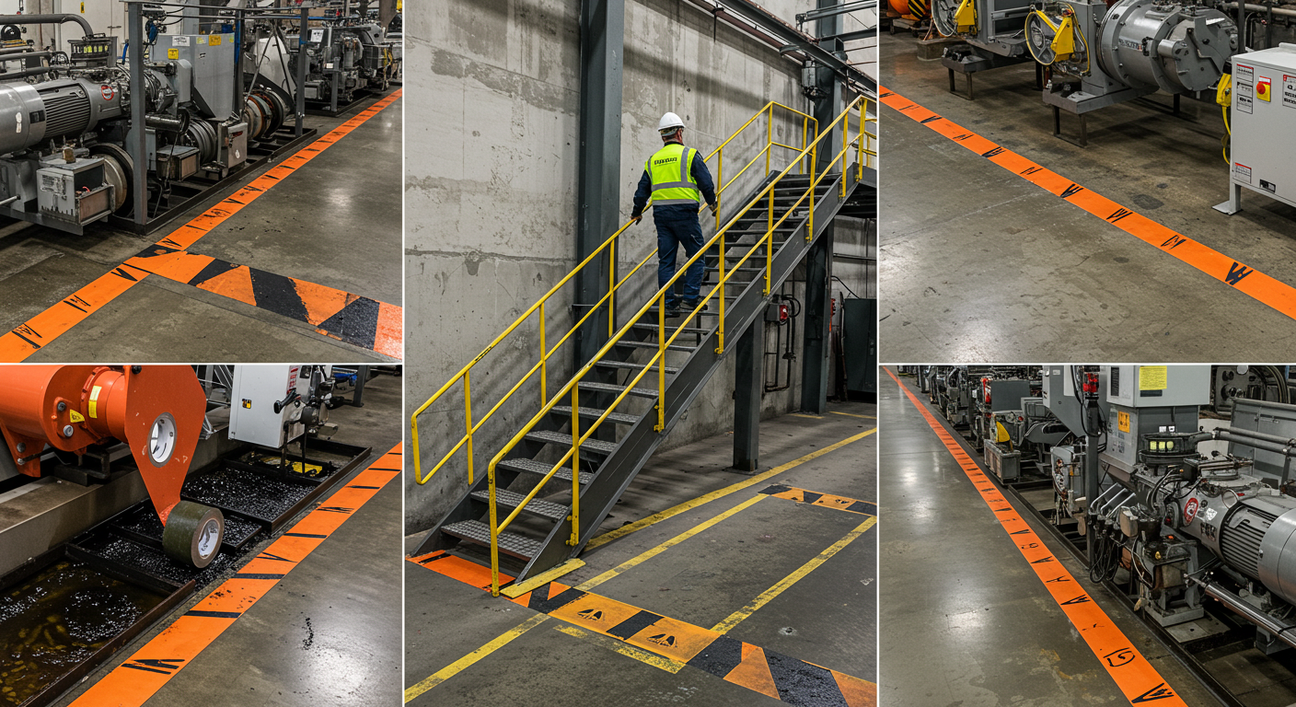

Australian warehouse floor marking standards outline specific requirements for marking pathways, hazards, storage areas, and other key zones inside an office. These standards specify the use of color-coded markings and affirmed materials, such as green vinyl tape for clear visual direction and specific security pointers. Proper placement and the use of durable materials help maintain visibility and safety.

Archford offers a range of compliant floor marking solutions, making it easy for warehouses to adhere to these regulations.

Benefits of Compliance

Complying with warehouse floor marking standards in Australia provides significant benefits:

Enhanced Safety

Proper floor markings help prevent accidents by clearly identifying hazardous zones and safe pathways. Materials like green vinyl tape and anti-slip solutions in high-traffic areas reduce the hazard of slips and falls.

Improved Effectiveness

Clear and organized markings streamline workflow by designating regions for specific tasks, supporting specialists and apparatus in moving more efficiently.

Reduced Obligation

Adherence to established standards minimizes non-compliance penalties and protects against liability from potential workplace incidents.

Common Types of Floor Marking Solutions

Choosing the right floor-checking materials is vital for compliance and durability. Common arrangements include:

Vinyl and Green Vinyl Tape

Perfect for high-traffic zones where permeability and security are important.

3M Intelligent Tape

Upgrades visibility, particularly in low-light conditions, making it fundamental for 24/7 operations.

Retro Intelligent Tape

Offers increased visibility for crisis exits and basic ranges that require to be seen from a separate or at night.

Archford gives an assortment of these high-quality items that meet Australian standards, ensuring your warehouse remains compliant and safe.

Best Hones for Executing Floor Marking

To guarantee successful and compliant floor stamping, take after these best practices:

Use Durable Materials

Invest in high-quality products like green vinyl tape and retro-reflective tape to enhance the safety and lifespan of your markings.

Follow Color Coding

Follow the color specifications outlined in the warehouse floor marking guidelines in Australia. For occasion, yellow is frequently utilized for pathways, whereas ruddy marks crisis areas.

Routine Reviews

Conduct customary reviews and supplant worn-out markings as required. Utilize fixing assessment labels to follow the condition of floor markings and other equipment.

Archford offers comprehensive assets and warehouse floor marking standards Australia guidelines to assist you in seamless implementation.

Challenges and How to Overcome Them

Maintaining compliance may present challenges such as tall activity, wear and tear, or ensuring visibility in low-light ranges. Here’s how to overcome these challenges:

Use Flexible Materials

Select solid items like 3M intelligent tape and green vinyl tape to ensure your markings stay intaglio under heavy usage.

Routine Updates

Schedule regular maintenance checks and supplant any worn-out tape or paint promptly.

Additional Safety Tools

Utilize complementary tools like butterfly valve lockout gadgets to enhance overall security, ensuring machinery is properly secured during maintenance.

Final remarks

Complying with warehouse floor marking standards in Australia is essential for maintaining safety, improving efficiency, and reducing liability in industrial settings. By using reliable products like green vinyl tape, 3M reflective tape, and retro-reflective tape, you can create a safe, well-organized, and compliant workspace. Archford is committed to providing the necessary tools and resources, such as rigging inspection tags and other safety solutions, to help you maintain a safe, compliant environment.

FAQs

What are warehouse floor marking standards in Australia?

These standards outline requirements for marking pathways, hazards, and storage areas to ensure safety and organization in warehouses.

Why is compliance important?

Compliance enhances safety, improves workflow efficiency, and reduces the risk of accidents and liabilities.

What materials are commonly used?

Materials like green vinyl tape, 3M reflective tape, and retro-reflective tape are ideal for floor marking.

How can I maintain my floor markings?

Regularly inspect and replace worn-out tape, using rigging inspection tags for easy tracking of maintenance.

What tools can improve safety further?

Using devices like butterfly valve lockout can help secure machinery during maintenance and enhance overall safety.