Specialized Safety Gloves for Electrical Work: What You Need to Know

Ensuring proper safety practices when working with electricity is vital to prevent accidents and injuries. One of the most important pieces of personal protective equipment (PPE) for such tasks is a safety glove. At Archford, we offer a range of safety solutions, including safety gloves, safety floor tape, and other essential products to help create a safe working environment. This blog will guide you through the types of electrical safety gloves, key features to look for, and best practices for their use.

Introduction

Using the right safety glove is crucial for protecting workers from electrical dangers. Electrical work poses unique dangers, and selecting gloves with the rectified details can be the contrast between security and serious injury. Proper utilization of safety equipment, paired with items like safety floor tape and lifting tag colors for organized areas, ensures comprehensive security protocols.

Types of Safety Gloves for Electrical Work

There are diverse sorts of security gloves tailored to various electrical tasks. Common types include:

- Insulated Gloves: These are designed to prevent electrical stuns and are regularly utilized near defensive calfskin gloves.

- Rubber Gloves: These give an essential layer of security and come in different voltage-rated classes.

- Composite Gloves: Combining elastic separator and calfskin, these gloves offer additional durability and grip.

For complete safety management, use a lockout bag to store all necessary PPE and lockout tools securely.

Key Highlights to See for in Electrical Security Gloves

When choosing a safety glove for electrical work, consider these essential features:

- Voltage Rating: Ensure the glove is rated for the specific voltage level you will be working with.

- Durability: Select gloves that can handle wear and tear over time.

- Grip: Great hold is vital when handling tools or machinery.

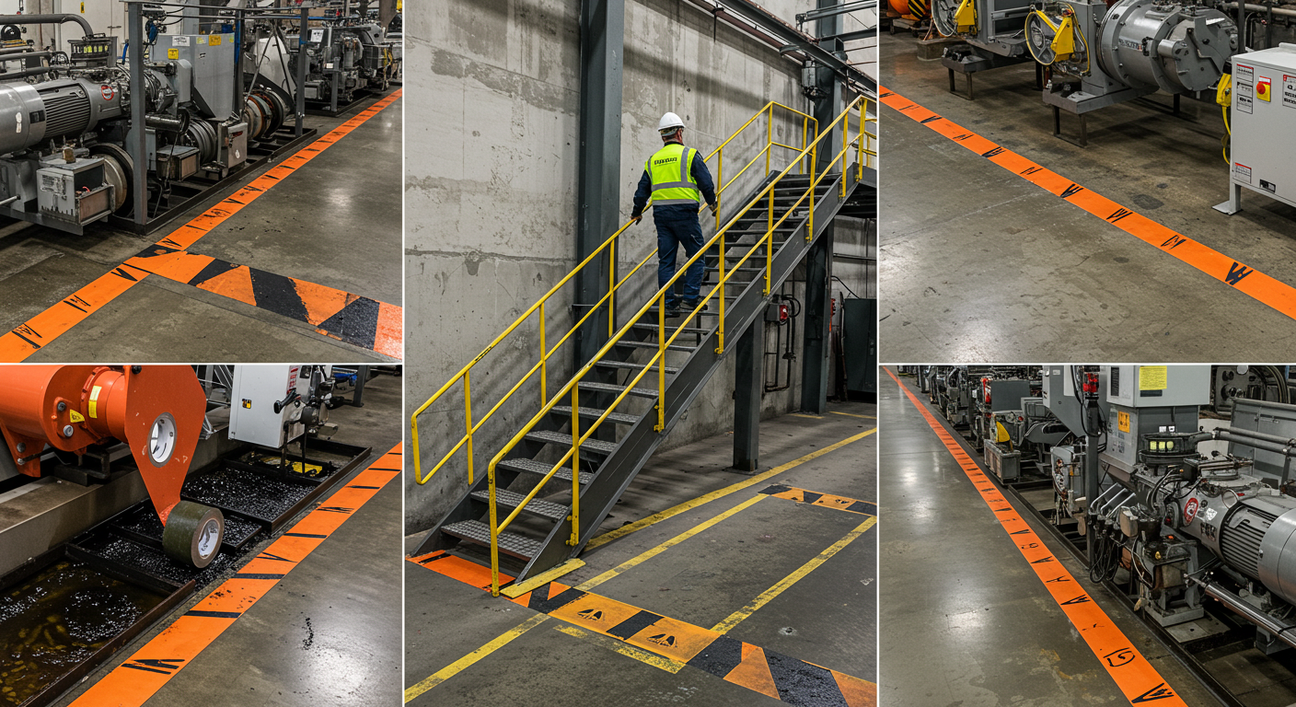

To complement the utilization of security gloves, apply security floor tape to mark off hazardous areas and keep work zones organized for improved visibility and safety.

Standards and Compliance

Ensuring that your security gloves meet relevant security standards is essential for workplace compliance. Check for gloves that meet ASTM or IEC measures for electrical work. Archford gives solutions to help maintain compliance, such as high-quality industrial label printer for sale options for creating clear names and security instructions.

Proper Use and Maintenance

- Regular Inspections: Before use, inspect gloves for any damage or wear. Referencing an OSHA Safety Signs Guide can help identify critical safety checks and warnings.

- Clean and Store Properly: Keep gloves clean and store them in a lockout pack to prevent contamination or damage, as advised in the OSHA Safety Signs Guide for proper safety practices.

- Periodic Testing: Test gloves periodically to ensure they maintain their protective properties, aligning with recommendations from the OSHA Safety Signs Guide for maintaining safety standards.

Using lifting labels and color codes to mark gear helps streamline the identification process, enhancing safety management during inspections.

Common Mistakes to Avoid

Avoid these common botches to guarantee ideal safety:

- Using Damaged Gloves: Always inspect your safety gloves for tears or punctures.

- Incorrect Sizing: Gloves that do not fit well can restrain ability and increment risks.

- Neglecting Customary Checks: Guarantee gloves are periodically tested for adequacy, especially in high-risk environments.

Closing reflections

Using the appropriate safety glove is fundamental for safe electrical work. Ensure that gloves meet required voltage ratings, are durable, and provide a reliable grip. Enhancing your safety protocols with tools such as safety floor tape, lifting tag colors, and keeping essential items in a lockout bag supports a comprehensive safety strategy. At Archford, we also offer industrial label printer-for-sale options to create detailed, durable labels for clear communication in your workplace. Following these best practices ensures a safer, more compliant working environment.

FAQs

Why are safety gloves important for electrical work?

Safety gloves protect workers from electrical shocks and injuries by providing necessary insulation and grip.

What features should I look for in electrical safety gloves?

Look for voltage ratings, durability, and good grip to ensure comprehensive protection.

How should I maintain my safety gloves?

Regularly inspect for damage, clean them, and store them in a lockout bag to prolong their life.

What other safety tools should I use with safety gloves?

Complement safety gloves with safety floor tape and lifting tag colors to mark zones and identify equipment.

Where can I get high-quality safety labels?

Archford offers industrial label printer-for-sale options for creating clear, durable safety labels.