Benefits of Integrating Barcode Label Printers with Your Inventory Software

In today’s competitive business landscape, effective inventory management is essential for productivity, safety, and accuracy. Integrating a barcode label printer with your inventory software can streamline your operations, reduce errors, and enhance efficiency across various workflows. This guide delves into the benefits of integrating barcode printing technology with inventory software and how it supports a well-organized and safer work environment, particularly for industrial and warehousing sectors.

Introduction

When managing stock in high-demand environments, combining inventory software and a barcode label printer can be invaluable. Not only does it enable exact item labeling, but it also helps track items throughout the supply chain. This integration is perfect for maintaining consistency, optimizing stock levels, and minimizing errors—critical benefits for facilities handling large volumes of items.

Streamlined Inventory Management

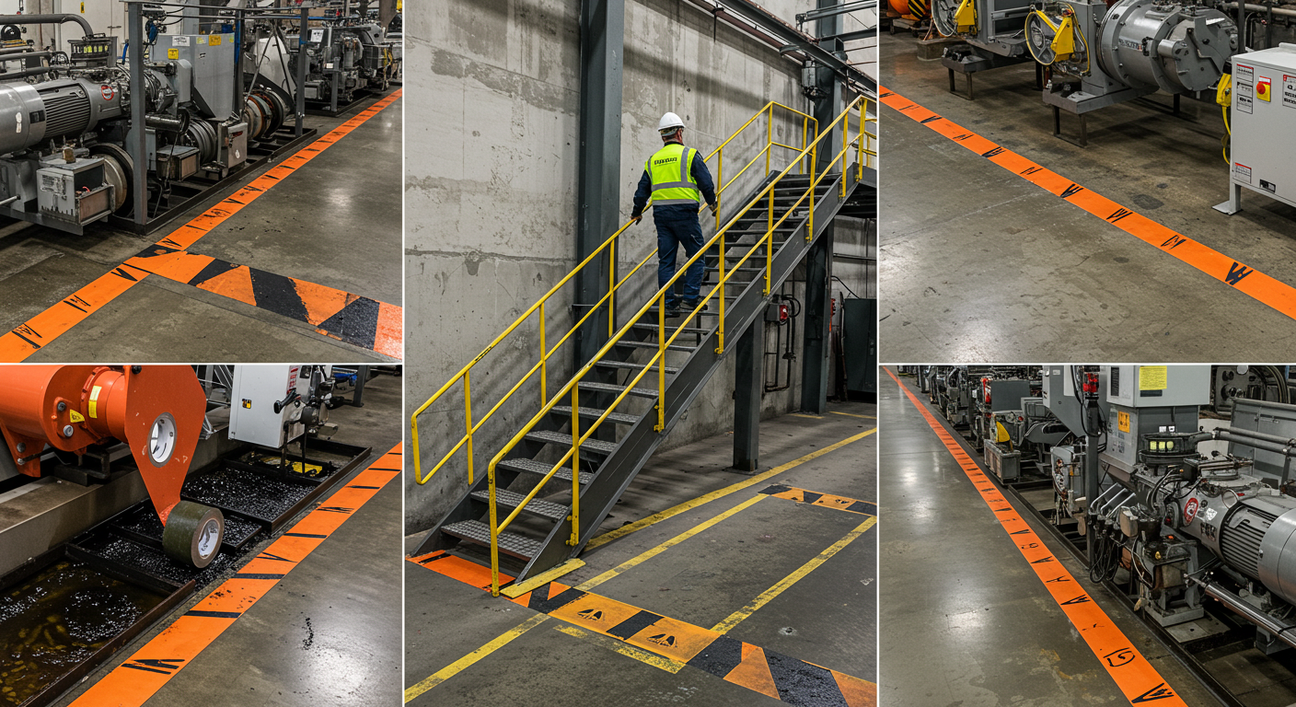

Integrating a barcode label printer with stock software simplifies inventory tracking and minimizes human mistakes. Names can be directly generated from the software, eliminating the requirement for manual input and ensuring each product is labeled precisely. For upgraded organization in industrial settings, floor spaces can be stamped with industrial floor tape to make designated areas for labeled inventory, further streamlining workflows.

Enhanced Tracking and Traceability

The integration permits precise item tracking across various stages of inventory management. By applying names utilizing a barcode label printer, you can follow items as they move through distinctive focuses, giving detailed visibility. For facilities handling hazardous items, safety protocols can also be upgraded by joining electrical plug lockout devices to ensure the secure handling of electrically fueled gear. Barcode-labeled products combined with color-coded zones marked by industrial floor tape make a safer, organized environment.

Improved Efficiency and Productivity

Manually labeling items can be time-consuming and error-prone. Integrating a barcode label printer with inventory software allows workers to label efficiently, speeding up workflows and reducing bottlenecks. Using lifting tags for heavy equipment provides clear handling instructions, enhancing organization and reducing workplace injuries. This system, combined with digital tracking, improves overall efficiency.

Cost Savings and Resource Optimization

Using barcode labels generated by an integrated system reduces operational costs by killing manual blunders and supporting precise following. By optimizing stock levels with real-time data, businesses can avoid overstocking or stock deficiencies, thereby saving on carrying costs. Moreover, well-marked regions and security conventions, like electrical plug lockout gadgets and lifting labels for specific items, further reduce costs by minimizing hardware downtime and working environment accidents.

Better Data Accuracy and Reporting

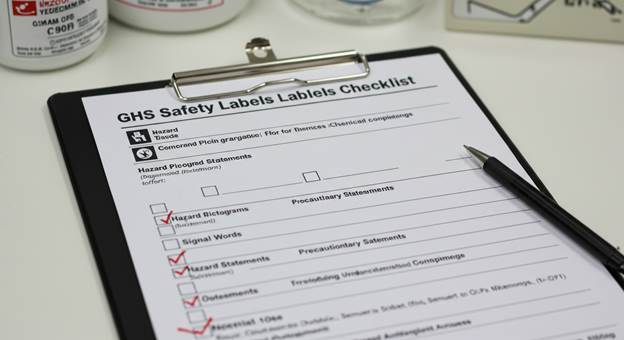

Integrating a barcode label printer with inventory software ensures accurate data collection, aiding informed decision-making with up-to-date stock information. Using green reflective tape to mark emergency exits and high-risk areas enhances safety, creating a well-organized, secure work environment through clear labeling and strategic marking.

Simplified Reordering and Stock Management

With inventory software, integrated barcode labeling can incite automatic reorders when the stock reaches a low threshold, helping to keep up optimal levels. This streamlines stock administration and guarantees your office is continuously well-supplied. By designating areas with industrial tape and using visible tags like lifting tags for equipment, reordering, and stock management become more efficient, as each thing is properly located and marked.

To sum up

Integrating a barcode label printer with inventory software enhances accuracy, efficiency, and safety. Facilities managing high stock volumes or hazardous equipment benefit from this streamlined process. Combined with tools like electrical plug lockout devices, lifting tags, and green reflective tape for emergency visibility, it ensures optimized inventory management, improved workflows, and cost reduction while maintaining a safe, organized environment.

Faqs

Why integrate a barcode label printer with inventory software?

For streamlined labeling, better tracking, and fewer manual errors.

How does this enhance safety?

Clear labeling supports organized workflows, with tools like industrial floor tape and electrical plug lockout adding safety.

Can it help with compliance?

Yes, accurate labeling aids compliance, especially with lifting tags and green reflective tape for safe zones

Is this suitable for small businesses?

Absolutely. It boosts efficiency and scalability for businesses of any size.