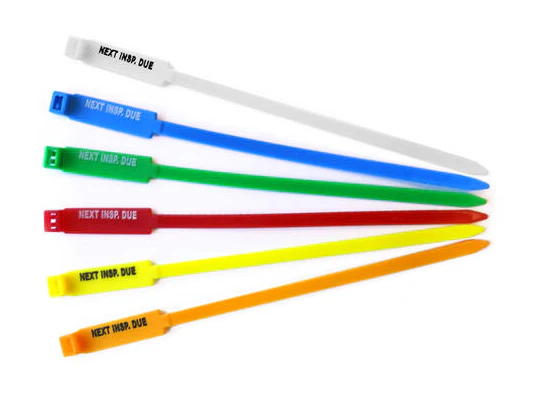

How to Track Quarterly Inspections with Color-Coded Inspection Tags

Maintaining safety and manufacturing quality control in industrial and commercial facilities requires structured and consistent inspections. One of the most effective ways to streamline this process is by using quarterly inspection tags for easy tracking and organization. At Archford, we provide a wide array of safety and organizational products to help you establish a thorough inspection system and maintain compliance with industry standards.

Introduction

In high-demand environments, regular inspections are essential for ensuring gear reliability and worker safety. Facilities that prioritize manufacturing quality control rely on organized inspection systems to uphold standards and maintain safety. A well-structured system using color-coded quarterly inspection tags can streamline the preparation, making it simpler to recognize review dates, statuses, and compliance needs at a glance.

Benefits of Utilizing Color-Coded Quarterly Assessment Tags

Implementing quarterly assessment labels gives different advantages:

- Quick Visual Identification: Color-coded tags allow employees to instantly recognize whether an item is up-to-date with reviews or due for review.

- Enhanced Security and Compliance: When utilized nearby security markers, such as help pack signs and review labels, help create a clear system that prioritizes safety and compliance.

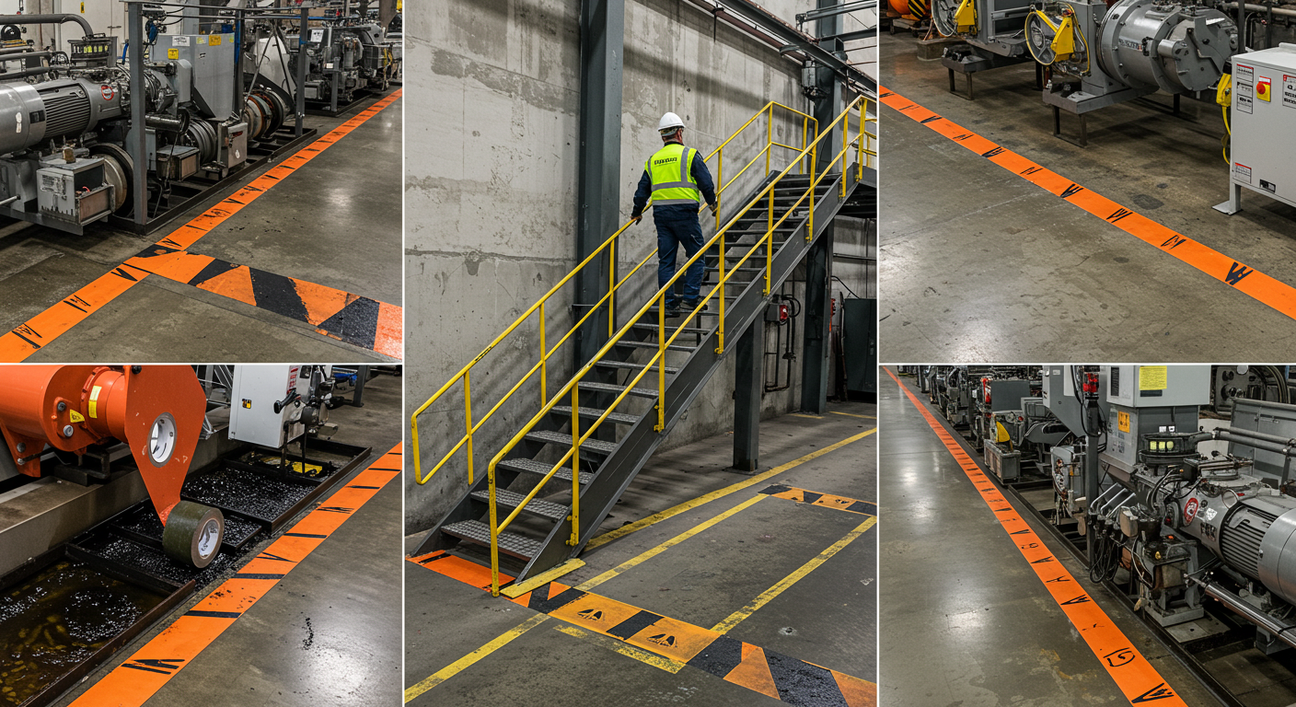

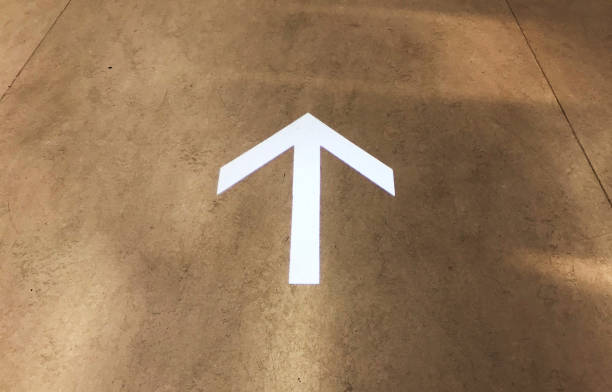

- Improved Organization with 5S Principles: The application of 5S floor tape in assigned review zones improves organization, adjusting with lean principles and reducing clutter.

Choosing and Implementing Color Schemes

Choosing the right color scheme for quarterly assessment labels is significant for clarity and effectiveness:

Consistent Quarterly Colors: Use a 5S Colour Code Chart to assign distinct colors for each quarter (e.g., red for Q1, blue for Q2) to ensure consistency and easy tracking.

Use of Solid Materials: Opt for durable labels that can withstand tough conditions and use printers to add review dates and statuses for a professional display.

Enhanced Visibility: Ensure labels are visible in dimly lit or busy areas by using bright, high-quality materials, guided by the 5S Colour Code Chart, for clear recognition and effective communication.

Setting Up Your Quarterly Inspection System

To establish an efficient inspection process with quarterly inspection tags, follow these steps:

- Plan a Quarterly Schedule: Outline a quarterly inspection timeline that ensures each piece of equipment is reviewed at standard intervals. Post this schedule in obvious areas around the facility.

- Designate Review Zones with 5S Floor Tape: Utilize 5S floor tape to mark designated review zones, making it less demanding for workers to find and assess equipment systematically.

- Label All Equipment Clearly: Utilize label printers to make solid, customized names that incorporate the review date, status, and following planned review. This makes strides in exactness and diminishes the potential for missed inspections.

Keeping up Security and Compliance

Beyond utilizing quarterly assessment labels, keeping up a secure and compliant work environment includes a few best practices:

- Secure Hardware with Discuss Valve Lockouts: Utilize discuss valve lockouts on hardware to avoid unauthorized utilization amid assessments or support. This added security degree ensures no one incidentally works apparatus that is not secure for use.

- Prominent Security Signage: Put a first aid kit sign in inaccessible areas so employees can rapidly locate first aid supplies in case of crises, fortifying a safety-first culture.

- Regular Overhauls and Replacements: Replace quarterly review tags promptly after each review cycle to keep data current and pertinent, guaranteeing that the status of equipment is always clearly communicated.

To wrap up

Using quarterly inspection tags in conjunction with tools like 5S floor tape, air valve lockouts, and label printers is an effective strategy for maintaining both safety and manufacturing quality control. These practices foster a proactive approach to safety, allowing employees to work in an environment that is well-organized, compliant, and optimized for productivity. Incorporating visual aids, such as a first aid kit sign, contributes to a comprehensive safety system, reinforcing a culture of safety and accountability. Together, these tools and practices help ensure a more efficient, compliant, and safer workplace.

FAQs

Why use color-coded quarterly inspection tags?

They provide visual clarity, making it easy to track inspection schedules and maintain compliance.

How do I choose the right color scheme?

Assign a unique color for each quarter (e.g., red for Q1, blue for Q2) to simplify tracking.

What tools help organize inspection areas?

5S floor tape is ideal for marking inspection zones, and label printers can create detailed tags.

How can I enhance safety during inspections?

Use air valve lockout devices and display a first aid kit sign for added safety.

What’s the benefit of regular tag updates?

Replacing quarterly inspection tags ensures accurate data and compliance.